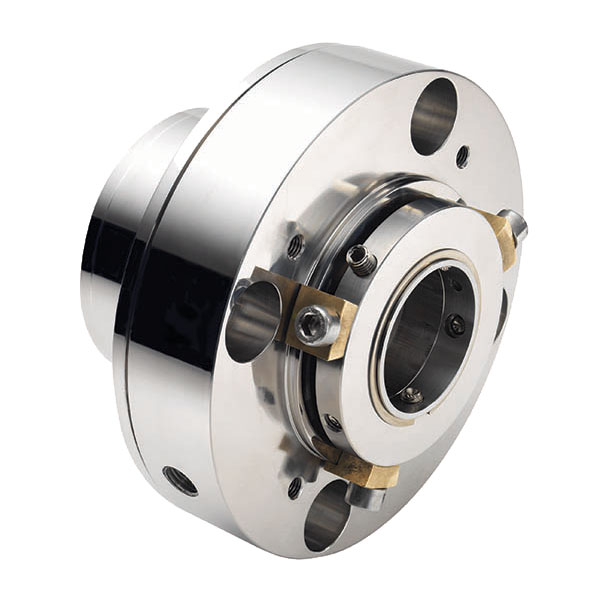

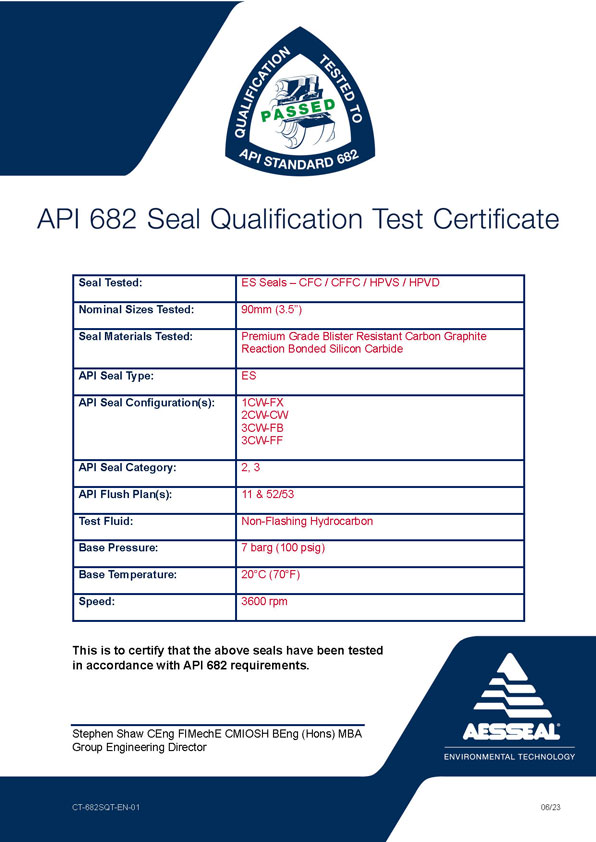

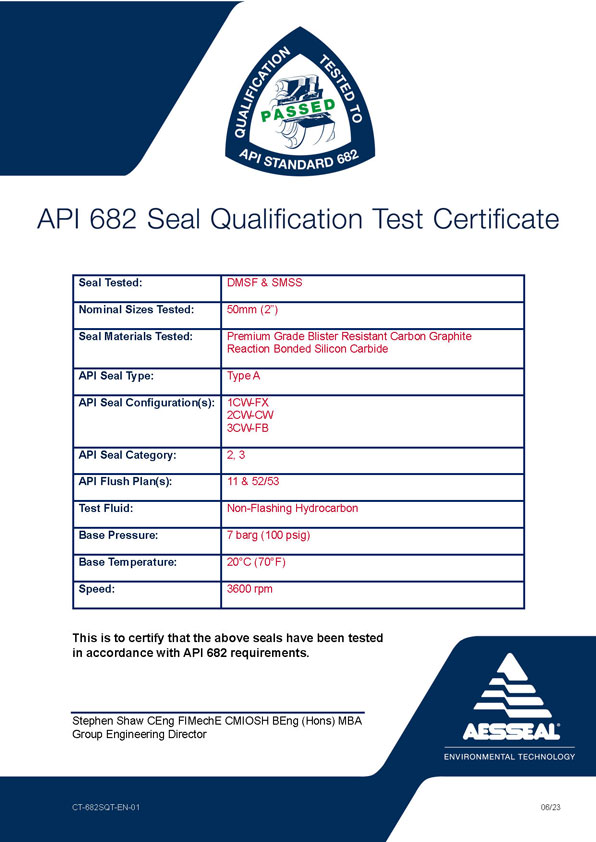

AESSEAL® have been providing API 682 compliant sealing solution to both end users and EPC companies in the oil and gas industry for many years.

The solutions deliver improved reliability supported by one of the best customer service records in the industry.

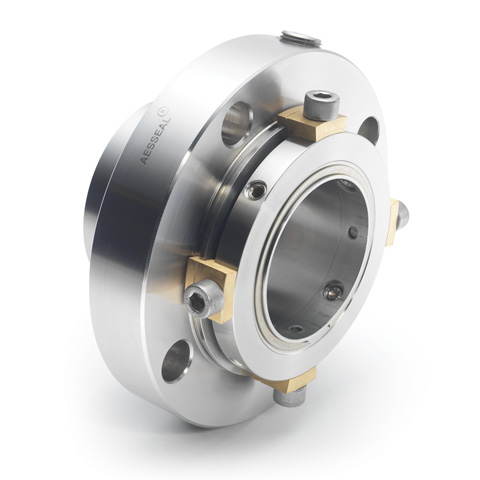

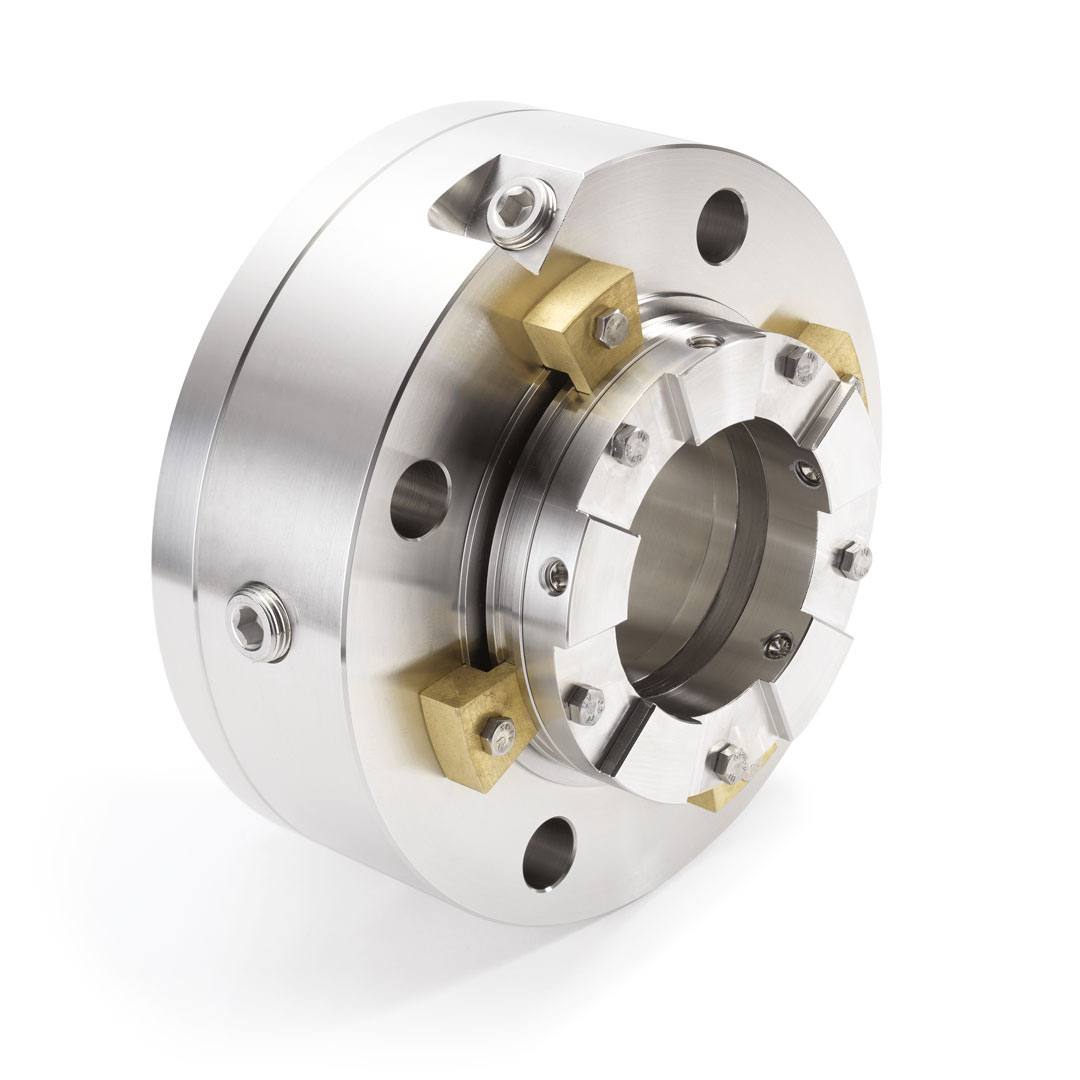

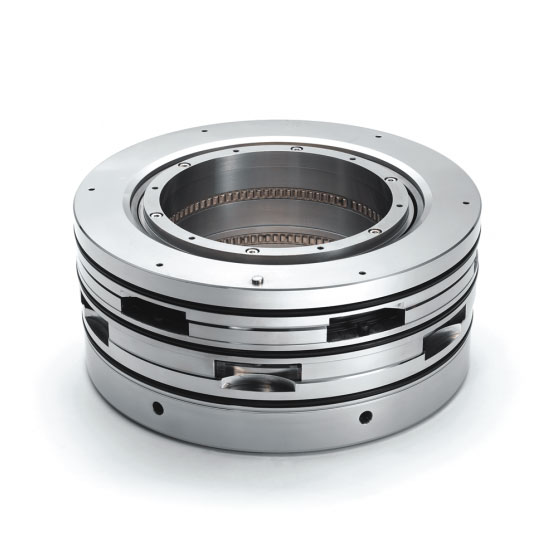

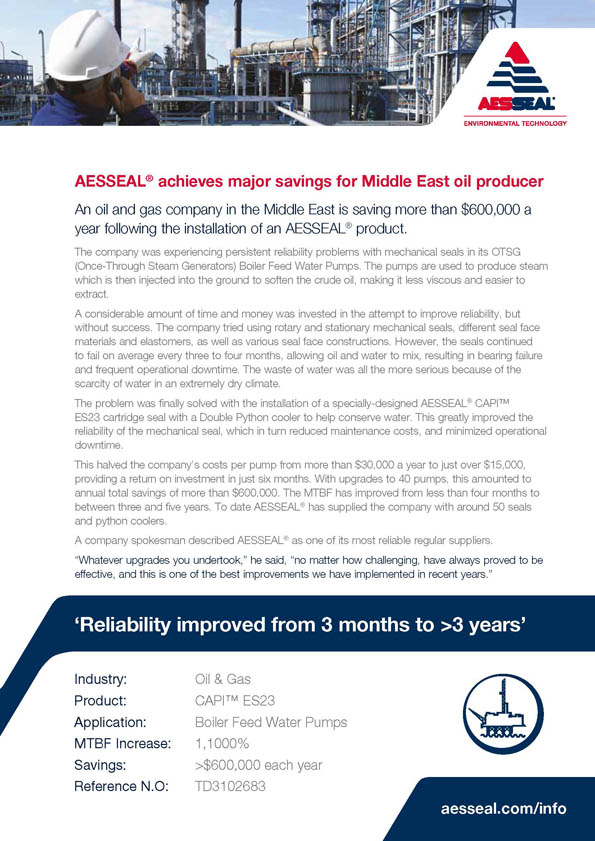

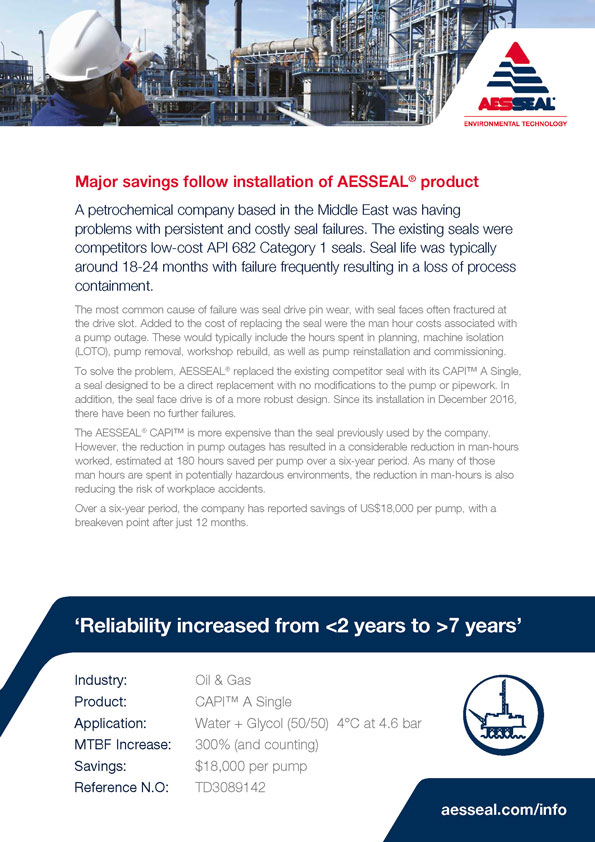

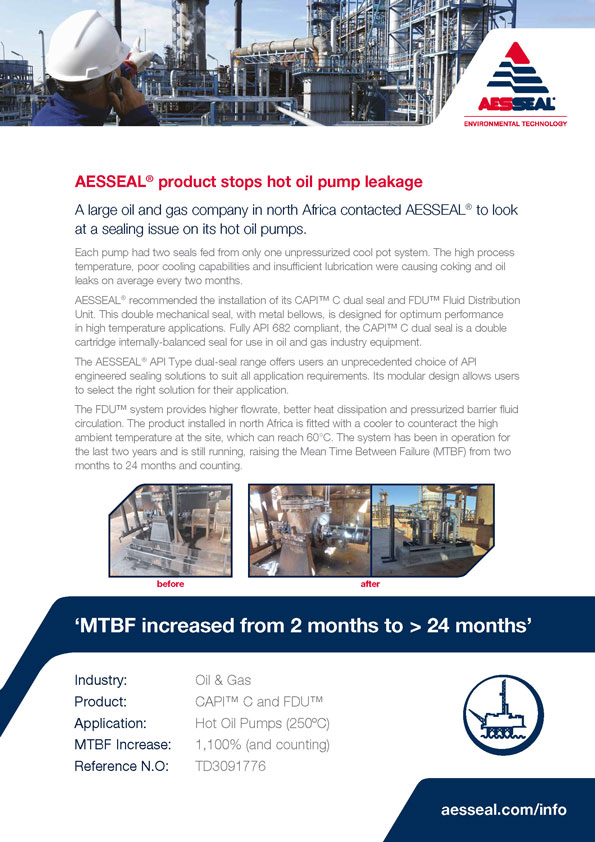

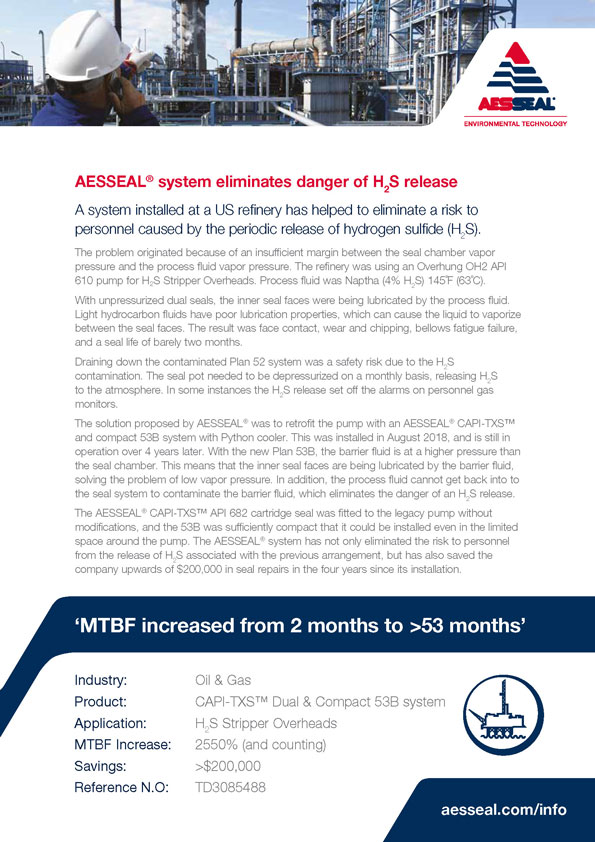

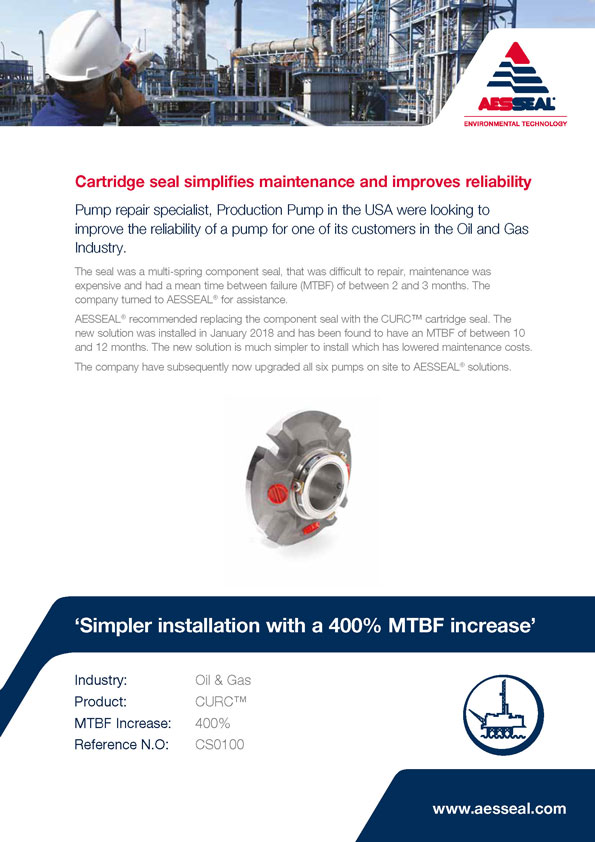

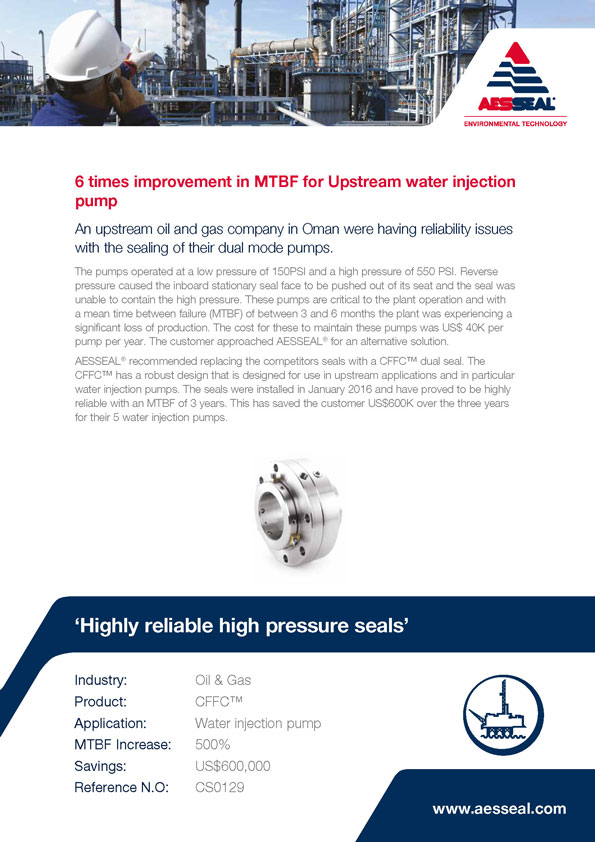

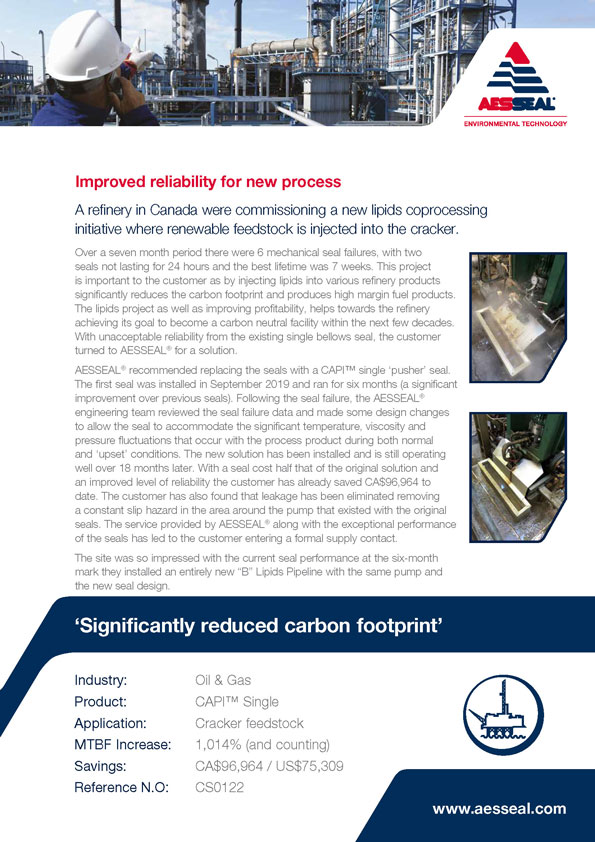

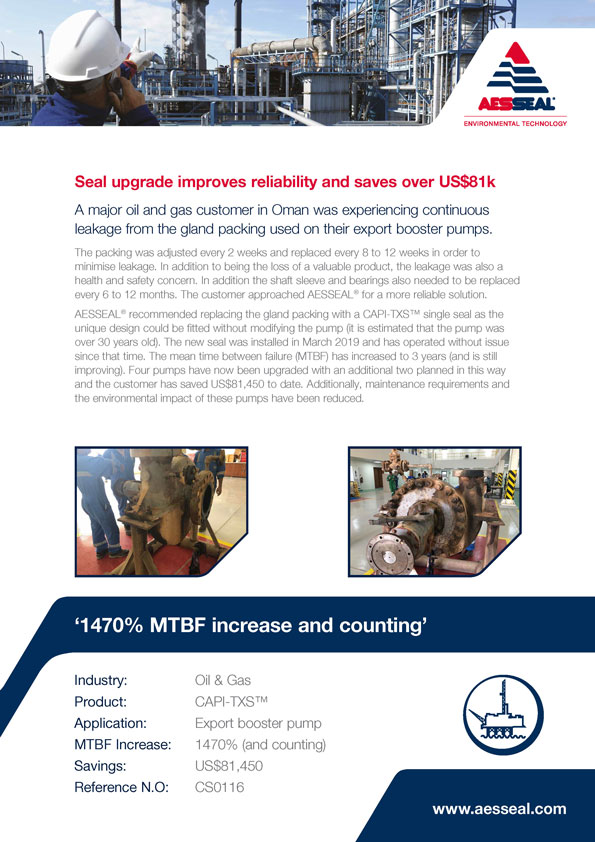

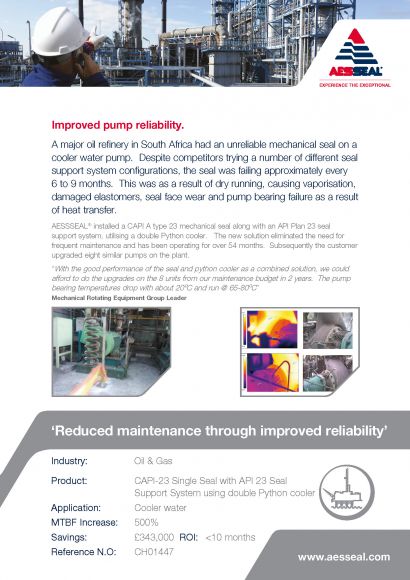

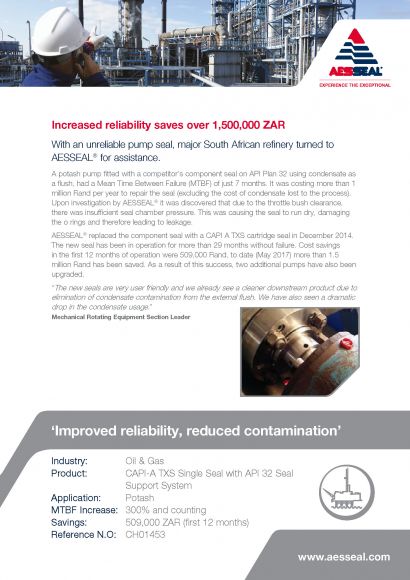

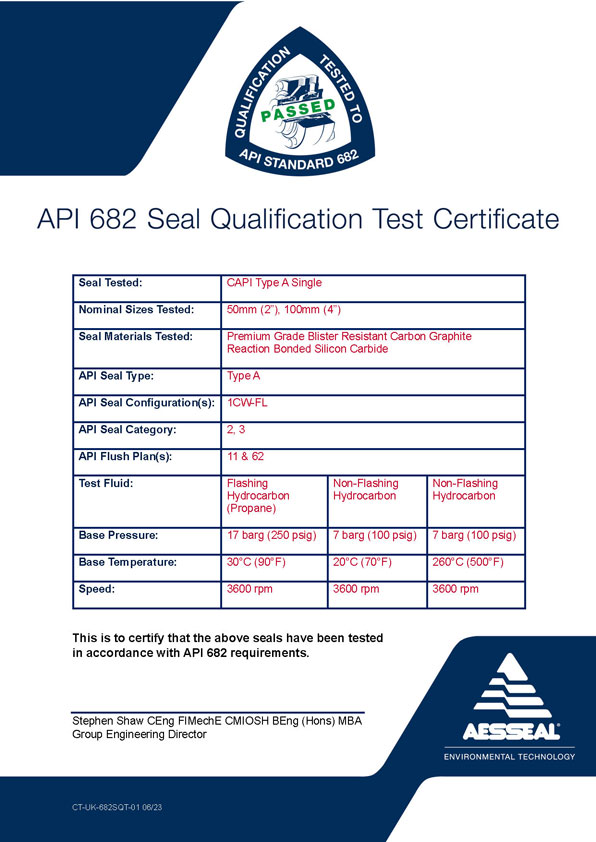

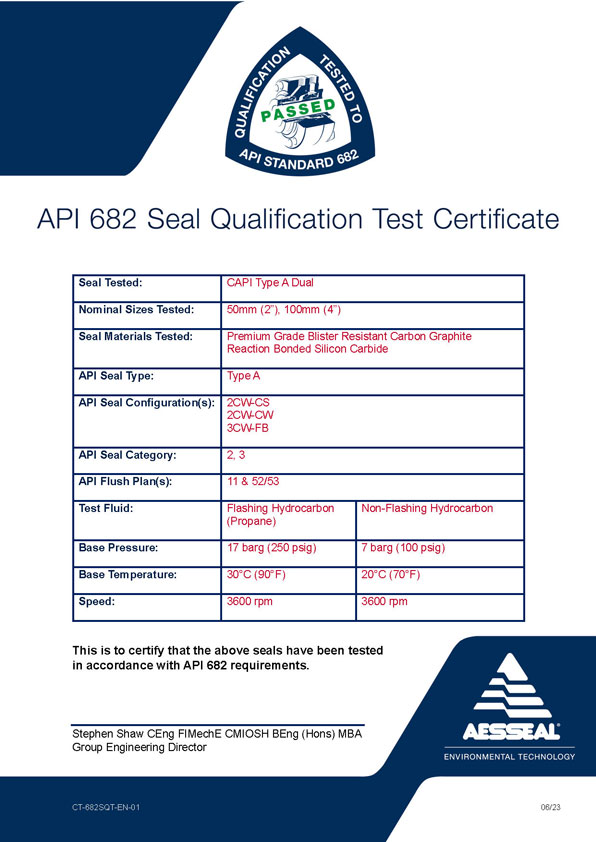

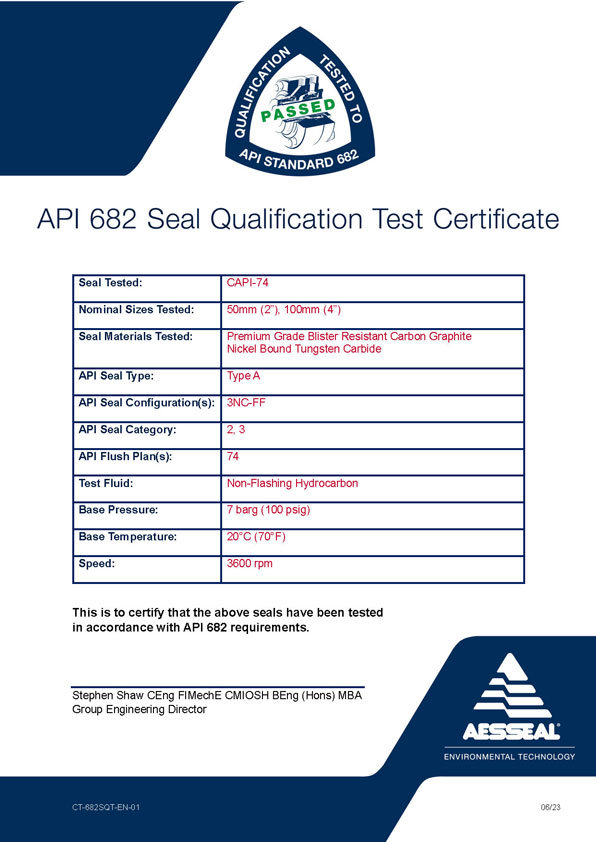

The CAPI™ range of seals is designed specifically for the oil and gas industry and design exist for many of the hundreds of pumps found. The unique CAPI-TXS range is designed to allow installation of dual seals in legacy pumps with smaller stuffing boxes, improving safety and reducing fugitive emissions without the need to modify the pump.

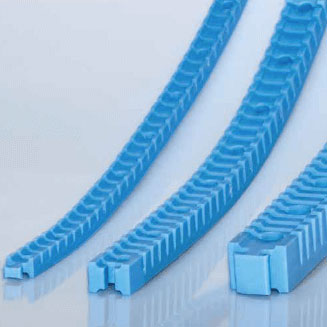

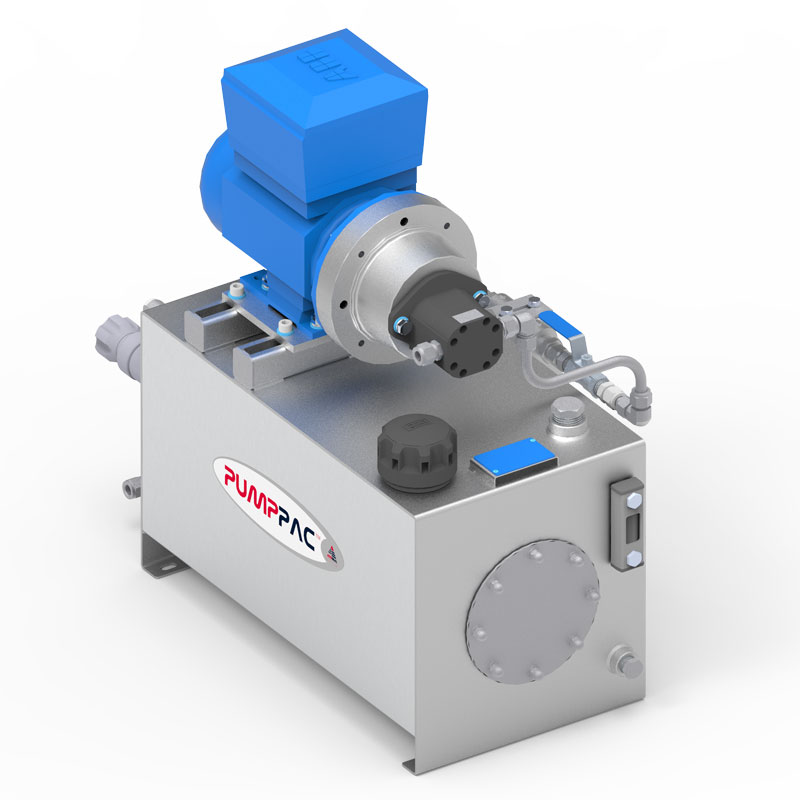

AESSEAL® offer a range of seal support systems suitable for use in the oil and gas industry. Our compression fit API53B system is particularly popular offering a range of options including the Python cooler, which offers superior cooling without the need for plant utility services. The modular construction ensures market leading product lead times.

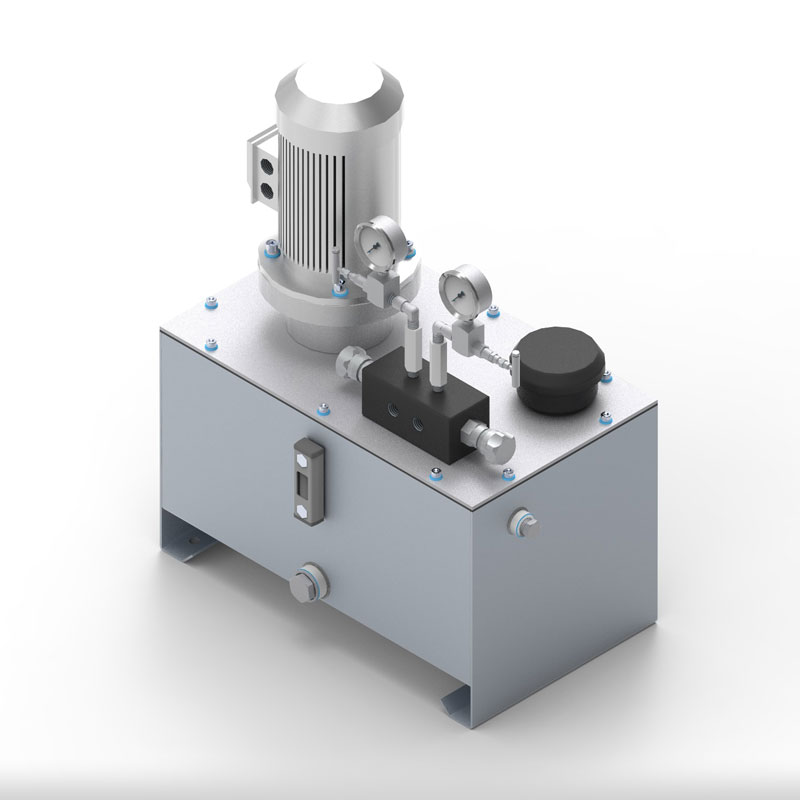

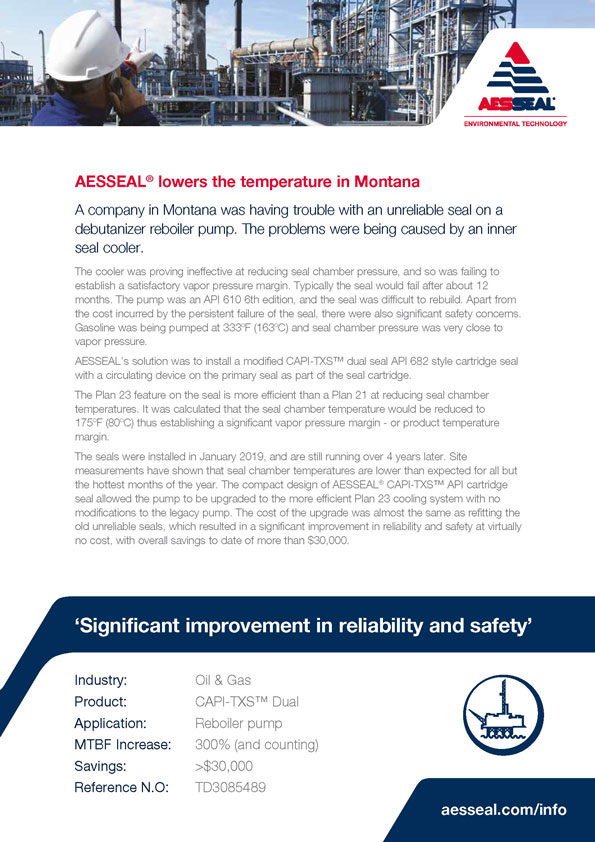

API Plans

We have seal support solutions available for all API Piping Plans; Our API Piping Plan documentation show widely used standardized flushing piping arrangements.